T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

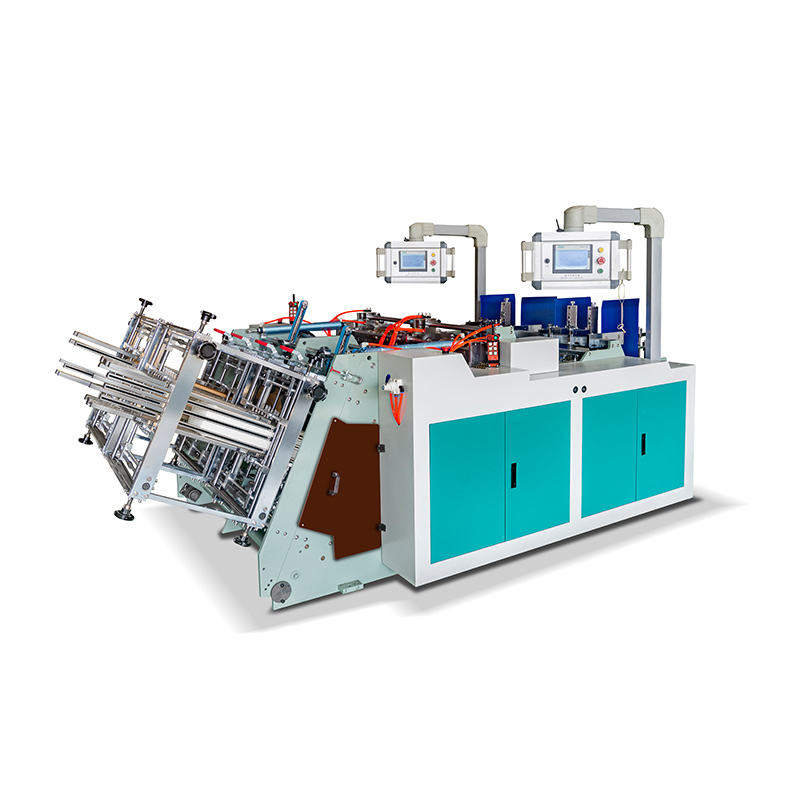

Are you curious about the costs of packsize machines? These innovative tools play a vital role in the packaging industry. Understanding the price of paper box machinery is crucial for businesses aiming to optimize their operations.

In this article, we’ll explore the factors affecting packsize machine costs and what you can expect when investing in this technology.

A packsize machine is designed to create custom-sized boxes on demand. This technology allows businesses to pack products more efficiently, reducing waste and saving on material costs. Unlike traditional paper box machinery, which produces standard-sized boxes, packsize machines adapt to the dimensions of the items being packed. This flexibility is crucial for companies looking to optimize their packaging processes.

There are various types of packsize machines available, each serving different needs:

● Semi-Automatic Packsize Machines

○ Require some manual input.

○ Ideal for smaller operations or businesses with lower volume needs.

○ Typically more affordable.

● Fully Automatic Packsize Machines

○ Operate independently with minimal human intervention.

○ Best for high-volume production.

○ Often equipped with advanced features like automated feeding and sealing.

Type | Key Features | Best For |

Semi-Automatic | Manual adjustments, lower cost | Small to medium businesses |

Fully Automatic | High speed, automated processes | Large-scale operations |

Packsize machines differ significantly from traditional paper box machinery. Here’s a quick comparison:

Feature | Packsize Machines | Traditional Paper Box Machinery |

Customization | Yes, creates boxes to fit specific sizes | Limited to standard sizes |

Efficiency | Reduces material waste | Often results in excess waste |

Speed | Adaptable based on demand | Fixed production speed |

Setup Time | Quick adjustments for different sizes | Longer setup for different sizes |

These differences highlight why many businesses are transitioning to packsize machines. They not only improve efficiency but also enhance sustainability by minimizing waste.

The cost of packsize machines varies widely based on features and capabilities. Here’s a breakdown of the price ranges:

● Price Range: $8,000–$25,000 USD

● Features:Basic functionality for small to medium operations.

○ Typically semi-automatic, requiring some manual input.

○ Suitable for businesses just starting with custom packaging.

● Price Range: $30,000–$80,000 USD

● Features:Enhanced speed and automation.

○ Often fully automatic, reducing labor costs.

○ Improved efficiency, making them ideal for growing businesses.

● Price Range: $100,000–$250,000+ USD

● Features:Advanced customization options.

○ High-speed production capabilities.

○ Designed for large-scale operations needing maximum efficiency.

Type | Price Range | Key Features |

Entry-Level | $8,000–$25,000 | Basic functionality, semi-automatic |

Mid-Range | $30,000–$80,000 | Fully automatic, improved efficiency |

Premium/Industrial | $100,000–$250,000+ | High-speed, advanced customization |

Several factors can influence the cost of these machines. Let’s break them down:

The functionality of the machine plays a significant role in its price. For instance, dual-station machines, which can handle multiple tasks simultaneously, tend to be more expensive than single-station machines. This added capability can lead to increased efficiency and reduced operational time.

Automation is another key factor. Machines equipped with servo-driven systems are generally pricier. However, they offer improved performance, speed, and precision. Investing in automation can lead to substantial savings in labor costs over time.

Customization can significantly impact costs. Designing molds for unique shapes often comes with additional expenses.

For example, a business that produces a unique product shape may find that customizing their packaging lowers per-unit costs when produced at scale. This investment can pay off by reducing material waste and improving product presentation.

Lastly, certifications can affect pricing. Certified machines (like CE or SGS) usually cost more than non-certified options. However, these certifications are essential for ensuring quality and compliance in international trade. They can also enhance the machine's resale value.

Factor | Impact on Cost | Explanation |

Functionality | Higher for dual-station | Increased efficiency and capability |

Automation Level | Higher for servo-driven | Improved speed and precision |

Customization Options | Additional costs | Unique designs can lower per-unit costs |

Certifications | Higher for certified | Ensures quality, compliance, and value |

Understanding current market trends is essential for grasping how packsize machine prices are determined. Recently, there has been a notable shift towards automation and efficiency. As businesses strive to reduce costs and enhance productivity, the demand for high-speed machines has surged.

● Speed vs. Cost: In the industry, there’s often a trade-off between speed and price. Machines capable of higher output, such as 200+ pcs/min, typically come at a premium. However, they can lead to greater overall savings through increased throughput.

Recent surveys indicate distinct pricing patterns based on speed categories. Here’s a quick overview:

Speed Category | Average Price Range |

100 pcs/min | $30,000–$50,000 USD |

200+ pcs/min | $80,000–$150,000 USD |

These benchmarks show how investing in faster machines can significantly impact initial costs, but may also yield better long-term returns.

After-sales support is a critical consideration when evaluating packsize machine costs. It’s not just about the purchase price; ongoing support can make a big difference in total expenses.

● Importance of After-Sales Support: Reliable after-sales service ensures that machines operate smoothly. It can minimize downtime, which is crucial for maintaining productivity.

When looking at warranties, businesses should consider additional costs. Here’s what to expect:

Warranty Type | Typical Additional Costs |

Standard Warranty | Usually included in price |

Extended Warranty | $2,000–$5,000 USD |

Support Packages | $1,000–$3,000 USD annually |

Investing in extended warranties and support packages can provide peace of mind. They often result in lower repair costs and extended machine life, making them worthwhile investments for many operations.

By carefully analyzing these factors, businesses can make informed decisions about their packsize machine purchases, balancing upfront costs against potential long-term savings.

When purchasing packsize machines, negotiating prices can lead to significant savings. Here are some effective tips:

● Know Your Market: Research current prices and trends in the paper box machinery market. This knowledge gives you leverage during negotiations.

● Discuss Minimum Order Quantities (MOQ): Suppliers often set MOQs. If you can negotiate these down, it may lower your overall costs.

Ordering multiple units can yield substantial discounts. Many suppliers offer tiered pricing, where the cost per machine decreases as the quantity increases. For example:

Quantity Ordered | Average Price per Unit |

1-5 | $30,000 |

6-10 | $28,000 |

11+ | $25,000 |

This strategy can be particularly advantageous for companies planning to scale operations.

Purchasing refurbished packsize machines can be a cost-effective option. However, it comes with its own set of benefits and risks.

● Benefits:

○ Lower initial investment.

○ Often comes with warranties or service agreements.

● Risks:

○ Potential for hidden issues.

○ Limited support compared to new machines.

When considering refurbished machines, quality control is paramount. Ensure strict QC checks are in place. Look for:

● Certification: Machines should be certified by reputable organizations.

● Inspection Reports: Request detailed reports on the machine's condition and any repairs made.

Evaluating the long-term return on investment (ROI) is crucial when buying packsize machinery. Here’s what to consider:

● Scalability: Choose machines that can grow with your business needs. Scalable machines adapt to increased production demands without requiring a complete overhaul.

● Efficiency: Investing in efficient models can lower operating costs over time.

Servo-driven models are known for their efficiency. They help reduce waste significantly. Here’s how:

● Adaptive Technology: These machines adjust to different packaging requirements, minimizing material waste.

● Market Trends: They can quickly adapt to changing market demands, ensuring you stay competitive.

By implementing these cost optimization strategies, buyers can make informed decisions that enhance profitability and operational efficiency.

In this article, we explored the costs associated with packsize machines. Key factors include market trends, pricing benchmarks, and after-sales support.

Understanding these elements is vital for making informed purchasing decisions. By considering negotiation strategies and potential savings, buyers can optimize their investments in paper box machinery.

Ultimately, knowing the true costs helps businesses thrive in a competitive market.

A: Consider speed, efficiency, after-sales support, and warranty options.

A: Analyze your production needs, packaging requirements, and scalability.

A: Yes, many suppliers offer financing plans to help manage costs.

A: Maintenance costs vary but include routine servicing and potential repairs.

A: Customization can increase initial costs but may enhance efficiency and reduce waste.