T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-11-12 Origin: Site

Across the beverage and packaging industries, one question keeps coming up: is it really worth transitioning from traditional plastic straw manufacturing to sustainable paper straw production? The short answer is yes — and not just for the planet. Switching to paper straw machine production can enhance a brand’s environmental credibility, secure long-term compliance with global regulations, and open new market opportunities driven by eco-conscious consumers. For companies ready to future-proof their business, this shift represents both a responsible and profitable investment.

As sustainability becomes a defining factor for business growth, beverage brands face increasing pressure to adapt their packaging choices. Plastic straws, once a convenient staple, are now one of the most recognizable symbols of environmental waste. The move toward paper straws has evolved from a marketing trend into a serious business strategy that influences consumer loyalty, corporate reputation, and compliance.

Evolving consumer habits: Surveys show that most consumers under 40 actively prefer sustainable packaging. They want to buy from brands that share their values and demonstrate responsibility through tangible actions like replacing plastics with biodegradable options.

Global plastic bans: Dozens of countries and regions — from the European Union to parts of Asia and North America — have restricted or banned single-use plastics. Beverage brands that continue to rely on plastic straws risk being left behind as retailers and distributors demand compliant alternatives.

Corporate responsibility goals: Major beverage chains and hospitality groups have publicly committed to reducing plastic waste by a specific percentage each year. This growing wave of accountability creates strong demand for sustainable straw production.

Plastic straws have become a liability rather than a convenience. Images of oceans polluted with microplastics directly affect how consumers perceive a brand. On the other hand, companies that use paper straws or operate their own eco-friendly production lines can position themselves as innovators. Investing in paper straw production is not just about following rules — it’s about leading the conversation around sustainability and gaining a competitive marketing edge.

The paper straw industry has evolved far beyond manual or low-speed production. Today’s paper straw machine technology is highly efficient, precise, and built for industrial-scale output. For manufacturers considering the switch, understanding what a modern line can deliver helps clarify its potential.

A well-designed production line can produce thousands of straws per hour, depending on the configuration. Machines are available for both glued and glue-free designs, providing flexibility for different markets. Glue-free technology, in particular, has gained attention for being safer and more environmentally sound.

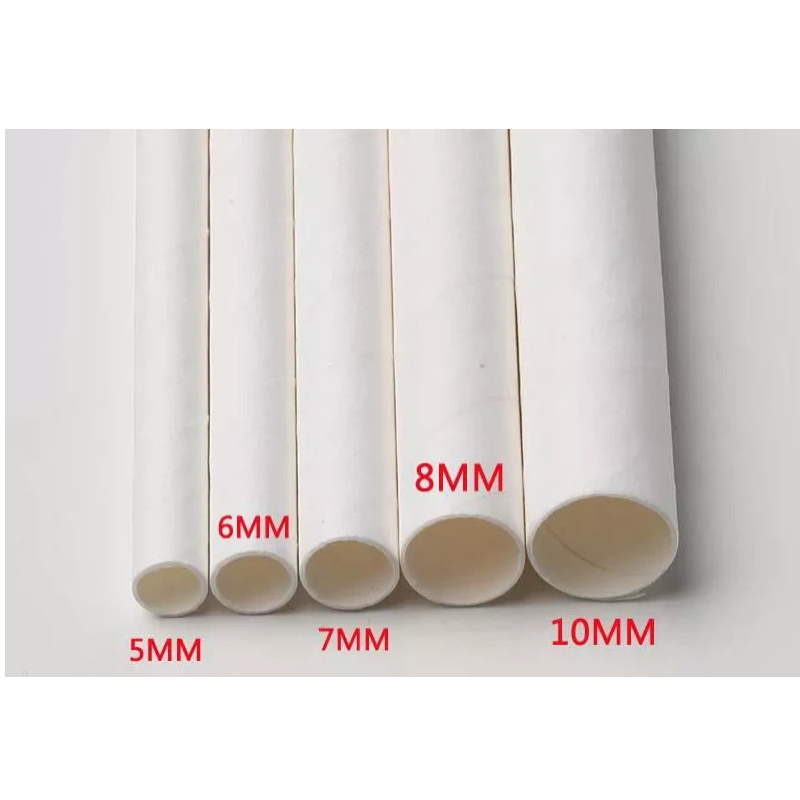

Paper straw machines can handle different diameters — from slim cocktail straws to large smoothie versions — and support custom lengths, patterns, and colors. For businesses serving multiple beverage categories, this flexibility makes production agile and efficient.

In addition, modern models include automatic feeding systems, precision cutting, and integrated drying units, reducing manual handling and boosting consistency.

Sustainability alone is not enough; quality assurance is equally important. A professional paper straw production line meets international food-grade standards, including CE and SGS certifications. High-end equipment maintains tight control over straw diameter and wall thickness, ensuring smooth performance even in cold drinks or high-humidity conditions.

By using multilayer paper rolls and strong biodegradable adhesives (or glue-free bonding), the resulting straws maintain integrity for hours without softening prematurely. For beverage brands and suppliers, this reliability directly impacts customer satisfaction and brand reputation.

While the initial investment in a new production line might appear significant, the long-term economics tell a different story. Companies that plan strategically can see a strong return on investment within a relatively short time frame.

Capital expenditure (CapEx) covers the purchase of the machine, installation, and initial setup. Operating expenses (OpEx) include paper raw materials, labor, energy consumption, and maintenance. The good news: paper raw materials are increasingly affordable, and new-generation machines are energy-efficient, with automated controls that minimize waste.

Moreover, paper rolls can be locally sourced, cutting import costs and delays. Compared with plastic, which is often subject to taxes or restrictions, paper offers stable supply chains and better long-term cost predictability.

Eco-friendly packaging is a marketing asset. Brands can command premium pricing or attract new customers simply by promoting their environmental responsibility. Many beverage companies report that switching to paper straws enhances their overall brand image and customer engagement, offsetting production costs through increased sales.

When combined with certifications and traceability — features that come naturally with modern paper straw manufacturing — the added transparency strengthens trust across retail and distribution channels.

The practicality of running a straw production line depends on a company’s available space, workforce, and operational capacity. Fortunately, the latest technology makes integration easier than ever.

Paper straw machines are compact, modular, and designed to fit within existing manufacturing spaces. A small workshop can accommodate one or two units for localized production, while larger facilities can install multiple lines for high-volume output. Basic utility requirements include stable electricity, air pressure, and ventilation.

Since the machines operate quietly and cleanly, they can be integrated into food-grade environments without disruption.

Automation is a key advantage of today’s systems. With digital controls, automatic feeding, and precise cutting, only a few operators are required to manage an entire production line. Training is minimal, as user-friendly interfaces simplify adjustments and monitoring.

This low-labor model not only reduces costs but also ensures consistent quality. In case of issues, remote diagnostic support and real-time monitoring options help operators maintain uptime and efficiency.

While global beverage giants have already moved toward sustainable packaging, paper straw production is also ideal for smaller and mid-sized companies seeking differentiation.

Independent beverage producers and co-packers can use in-house straw production as a branding tool. Offering customized paper straws — with printed logos, colors, or themes — helps products stand out on shelves. It also ensures consistent supply and eliminates dependence on external suppliers with long lead times.

For co-packers, integrating straw production means added value for clients who want turnkey eco-friendly packaging.

Hospitality businesses such as cafés, resorts, and event organizers increasingly prioritize sustainable materials. Producing their own paper straws allows them to align their branding with eco-conscious practices. For example, a hotel chain might offer personalized paper straws featuring its logo, enhancing both presentation and brand storytelling.

Event organizers can also benefit from small-batch runs, creating custom designs for festivals, corporate events, or eco-themed campaigns.

Behind every efficient paper straw production line is reliable machinery — and that’s where Wenzhou Hongshuo Machinery Co., Ltd. (HS Machinery) stands out. Based in the hometown of machinery innovation, Wenzhou, HS Machinery has spent years perfecting the design, manufacturing, and service of automated equipment.

Our paper straw machines are built for performance, durability, and compliance with international standards such as CE, SGS, and ISEGA. We offer both glued and glue-free options to meet varied market demands, and our dedicated after-sales team provides installation, training, and technical support worldwide.

Partnering with HS Machinery means more than buying equipment — it’s about gaining a trusted technical ally that understands the sustainability goals of modern manufacturers.

Transitioning from plastic to paper straw manufacturing is more than an environmental decision — it’s a forward-thinking business move that positions brands for success in an eco-driven market. With advanced paper straw production equipment from Wenzhou Hongshuo Machinery Co., Ltd., companies can align profit with responsibility, gain consumer trust, and secure a sustainable future. To start your journey toward greener production, contact us today for a tailored consultation and discover how HS Machinery can bring your sustainability goals to life.

1. What is the production capacity of a modern paper straw machine?

Depending on configuration, a high-speed line can produce thousands of straws per hour, covering multiple sizes and types, from cocktail to smoothie straws.

2. Are glue-free paper straws durable enough for beverages?

Yes. Glue-free bonding technology developed by HS Machinery ensures high structural integrity and full compliance with food-grade standards, even for cold or carbonated drinks.

3. How much space is needed to install a paper straw machine?

A compact production line requires limited space, often fitting within an existing workshop. Modular setups allow easy expansion as demand grows.

4. Why choose HS Machinery for paper straw production?

HS Machinery provides CE- and SGS-certified equipment, efficient automation, glue-free options, and reliable after-sales service — making it a trusted partner for sustainable production.