T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Have you ever wondered how products are efficiently packaged? Packaging machines play a crucial role in various industries, from food to retail.

In this article, we’ll explore what packaging machines are and their significance. You’ll learn about paper box machinery and its impact on modern packaging solutions.

Paper box machinery refers to equipment specifically designed to create, assemble, and package boxes made from paper or cardboard. It plays a vital role in the packaging industry, ensuring that products are securely and efficiently packaged. These machines streamline the production process, reducing labor costs and increasing output.

When we talk about paper box machinery, we’re focusing on various types of machines used in the packaging process. This includes machines for making, folding, gluing, and sealing boxes. Each type of machine has a unique function, contributing to the overall efficiency of packaging operations.

Paper box machinery is versatile and can handle a wide range of products. Here’s a quick look at some common items packaged using this machinery:

● Food Products:

○ Takeout containers

○ Snack boxes

○ Frozen food packaging

● Retail Items:

○ Gift boxes

○ Cosmetic packaging

○ Apparel boxes

● Industrial Goods:

○ Electronics packaging

○ Hardware boxes

○ Shipping cartons

1. Speed: Many machines can produce hundreds of boxes per minute.

2. Customization: They can be adjusted to create different box sizes and styles.

3. Efficiency: Automated processes reduce the need for manual labor.

Feature | Description |

Speed | High output rates, often exceeding 300 boxes/min |

Customization | Flexible settings for various box designs |

Automation | Reduces manual intervention, enhancing efficiency |

Paper box machinery is essential for businesses looking to optimize their packaging processes. It not only improves productivity but also enhances the quality of packaging, ensuring products reach consumers in perfect condition.

In the world of packaging, several key machines are essential for producing paper boxes. Each type has its unique functionality and applications. Let’s dive into the core types of paper box machinery.

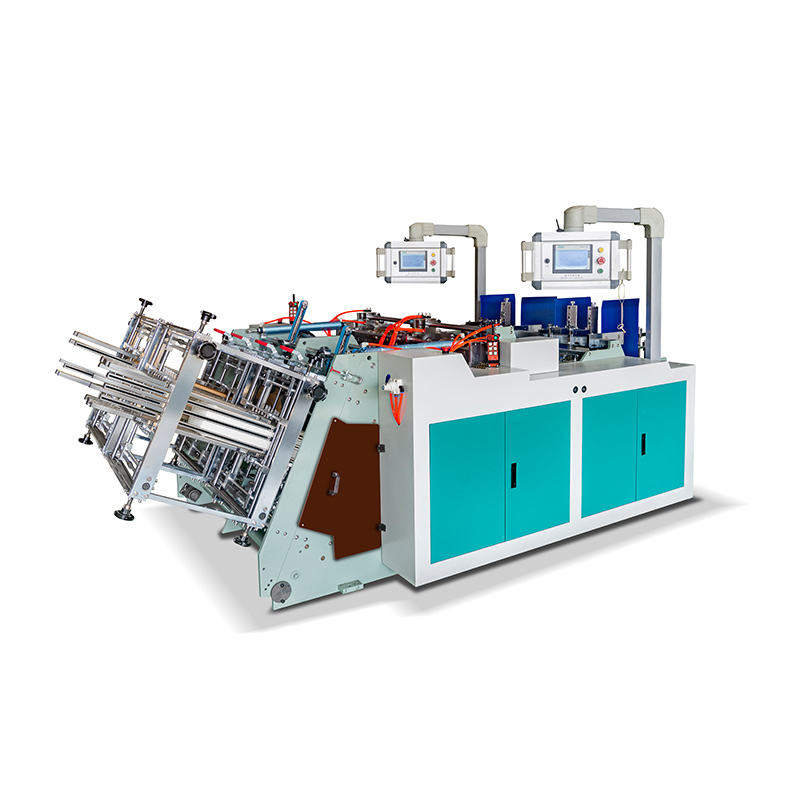

The paper box making machine is designed to create boxes from flat sheets of paper or cardboard.

● Description and Functionality: This machine cuts, folds, and glues paper to form boxes. It can operate in either single or double stations, allowing for varied production speeds.

● Key Features:

○ Single/Double Stations: Offers flexibility in production capacity.

○ Servo-Driven Precision: Ensures accurate cuts and folds for high-quality boxes.

● Applications:

○ Used for food boxes, like takeout containers.

○ Ideal for cake boxes and other specialty packaging.

Custom molds play a significant role in this process.

● Importance: They allow for unique box designs tailored to specific products, such as KFC-style burger boxes. This customization enhances brand identity and product presentation.

Next, we have the carton forming machine.

● Definition and Specific Functions: This machine assembles flat cartons into 3D shapes, ready for filling.

● Techniques Used: It employs methods like vacuum suction, water-based glue, and hot-melt adhesive for secure assembly.

● Production Capacity Details:

○ Can produce a high volume of cartons per minute.

○ Handles various paper weights, typically between 150–600 gsm.

This machine is versatile, accommodating different paper types. It ensures that businesses can use it for various packaging needs.

The folder gluer is another crucial machine in the packaging process.

● Purpose and Capabilities: It folds and glues boxes at high speed, making it suitable for large production runs.

● High-Speed Performance: This machine integrates well with other equipment, enhancing overall efficiency.

● Target Markets: Primarily serves e-commerce and fast-moving consumer goods (FMCG) packaging.

One notable feature is the zig-zag feeding mechanism.

● Benefits: It provides stability during production, reducing the risk of jams and ensuring smooth operation.

Finally, the automatic carton sealer/closer plays a vital role in the packaging line.

● Functionality: This machine closes pre-formed boxes securely, preparing them for shipment.

● Benefits of Automation: Automation significantly reduces manual labor, increasing efficiency and consistency.

To enhance box strength, these machines often include:

● Corner-Flap Reinforcement: This feature ensures that boxes maintain their shape and integrity, even under pressure.

Machine Type | Key Functionality | Target Products |

Paper Box Making Machine | Creates and assembles boxes | Food boxes, cake boxes |

Carton Forming Machine | Forms 3D cartons | Various retail products |

Folder Gluer | Folds and glues boxes | E-commerce, FMCG packaging |

Automatic Carton Sealer/Closer | Closes pre-formed boxes | All types of packaged goods |

These core types of paper box machinery are essential for businesses looking to enhance their packaging processes. Each machine serves a specific purpose, contributing to the overall efficiency and effectiveness of packaging operations.

In the competitive landscape of packaging, certain features set paper box machinery apart. These innovations enhance efficiency, flexibility, and sustainability, making them essential for modern businesses.

Servo technology is a game changer in the realm of packaging machinery.

● Explanation of Full-Servo Systems:

● Full-servo systems use advanced motors to control every movement with precision. This technology allows for accurate positioning and timing, which is critical in high-speed production environments.

● Advantages:

○ Precision: Ensures consistent quality across every box produced.

○ Speed: Increases production rates significantly.

○ Energy Efficiency: Reduces power consumption, lowering operational costs.

Having independent double stations is another key feature.

● Benefits for High-Speed Production:

These stations can operate simultaneously, achieving production rates of 60–300+ pieces per minute. This capability is crucial for meeting high demand without sacrificing quality.

Customization options are vital for businesses targeting specific markets.

● Importance of Mold Flexibility:

The ability to quickly change molds allows manufacturers to adapt to various product requirements. This flexibility is essential for niche markets that demand unique packaging solutions.

● Examples of Quick Turnaround for Niche Markets:

Businesses can swiftly produce specialized boxes, such as those for gourmet food or seasonal products, enhancing their market responsiveness.

Offering 24-hour design support provides a significant competitive edge.

● Competitive Edge in Mold Design and Production:

This service allows companies to rapidly develop and implement new designs, keeping them ahead of competitors.

Sustainability is becoming increasingly important in packaging.

● Role of Sustainability in Packaging Machinery:

Eco-friendly designs incorporate materials and processes that minimize environmental impact. For instance, using water-based glue instead of traditional adhesives is a step toward greener practices.

● Use of Water-Based Glue and Certifications (CE/SGS):

These certifications ensure that the products meet international safety and environmental standards, appealing to eco-conscious consumers.

Sustainable practices align well with global trends in packaging.

● Importance in Food Packaging:

For example, using PE-coated paper for lunch boxes meets both safety and sustainability standards, making it a preferred choice for food manufacturers.

When comparing machines, speed and efficiency are critical factors.

● Comparison of Top-Tier Machines vs. Basic Units:

Top-tier machines offer advanced features that enhance productivity compared to basic models. These include faster setup times and improved operational efficiency.

● Features That Enhance Setup Times and Operational Efficiency:

Innovations such as automatic calibration and quick-change setups streamline the production process, allowing for more efficient operations.

Modern machines often come equipped with touchscreen interfaces and auto-test modes.

● Innovations That Simplify Operation and Reduce Downtime:

These features make it easier for operators to manage the machines, reducing training time and minimizing errors during production.

Feature | Description | Benefits |

Servo Technology | Full-servo systems for precise control | Increases speed and efficiency |

Independent Double Stations | Operate simultaneously | Achieves high production rates |

Customization Options | Flexible mold designs | Quick adaptation to market needs |

Eco-Friendly Design | Sustainable materials and processes | Appeals to environmentally conscious consumers |

Speed and Efficiency | Advanced features for fast operations | Reduces setup times and downtime |

These features collectively enhance the competitiveness of paper box machinery, enabling businesses to meet the demands of a dynamic market.

The paper box machinery market is evolving rapidly. Several trends are shaping its future, driving innovation and competitiveness.

One major trend is the rise of niche applications.

● Focus on Specific Verticals:

Industries like fast food and premium packaging are looking for specialized solutions. For instance, fast food chains require efficient packaging for quick service, while luxury brands need elegant packaging that enhances product appeal.

● Innovations:

Technologies such as visual inspection systems and robotic integration are becoming standard. These innovations improve quality control and streamline production processes.

There’s also a growing need for machines designed for delicate product handling.

● Growing Need:

As more businesses offer fragile items, packaging machinery must adapt. Machines capable of handling delicate products ensure that items reach consumers intact, enhancing customer satisfaction.

Modular design is gaining traction, especially among small and medium enterprises (SMEs).

● Benefits of Scalable Solutions:

Modular systems allow businesses to start small and expand as needed. This scalability is crucial for SMEs that may not have the budget for large, complex machinery.

● Examples of Add-Ons:

Features like UV printers and labelers can be added as the business grows. This flexibility enables companies to customize their operations based on specific needs.

Modular designs offer significant advantages over rigid systems.

● Advantages of Modularity:

They provide cost-effective upgrades, allowing businesses to invest incrementally. This approach minimizes financial risk while maximizing operational efficiency.

There’s a clear distinction between entry-level and high-end models in the market.

● Budget-Friendly Options:

Startups often seek affordable machines that meet basic needs. These entry-level models provide essential functionalities without breaking the bank.

● Features of Premium Models:

On the other hand, high-end models target larger manufacturers. They come equipped with advanced features, ensuring high-speed production and superior quality control.

A notable feature in premium models is IoT connectivity.

● Benefits of Remote Diagnostics:

This technology allows for real-time monitoring and diagnostics. Manufacturers can perform maintenance remotely, reducing downtime and enhancing productivity.

Trend | Description | Benefits |

Niche Applications | Focus on specific industries | Tailored solutions for diverse needs |

Modular Design | Scalable solutions for SMEs | Cost-effective upgrades and flexibility |

Entry-Level vs. High-End | Budget-friendly vs. premium options | Wide range of choices for different businesses |

IoT Connectivity | Remote diagnostics and monitoring | Increased efficiency and reduced downtime |

These trends highlight how the paper box machinery market is adapting to meet diverse consumer needs while maintaining a competitive edge.

In exploring packaging machines, we learned about their crucial role in various industries.

Key points include the impact of niche applications, modular designs, and the differences between entry-level and high-end models.

The future of paper box machinery looks promising, driven by innovation and sustainability.

We encourage readers to explore options that best fit their packaging needs.

A: Benefits include increased efficiency, cost savings, and improved product protection. They also support eco-friendly practices.

A: Consider factors like production volume, product type, and available space. Assess features and scalability options.

A: Regular cleaning, lubrication, and inspection are essential. Follow the manufacturer’s guidelines for optimal performance.

A: Yes, many machines offer customization options, including mold flexibility and additional features for niche applications.

A: Costs vary widely based on features and capabilities, ranging from a few thousand to several hundred thousand dollars.