T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-10-30 Origin: Site

You use a paper straw machine to make paper straws fast and with good quality. Many people pick paper straws because they want eco-friendly and lasting choices. The world paper straw market is growing very quickly.

In 2024, the market size was up to USD 2.63 billion.

Experts think it will keep growing fast, with some saying the CAGR will be over 15% in the next years.

People want paper straws because governments and buyers care about nature. But making paper straws uses a lot of wood pulp, water, and energy. This can hurt the climate and forests.

Pick food-grade paper with a biodegradable coating. This makes straws strong and safe. The coating helps straws last in drinks. It also lets them break down after use.

Use water-based glue that is safe for food. This glue holds the straws together. It is also good for the environment.

Use machines to make straws faster. Automation helps make more straws each hour. It also cuts down on waste.

Check straws often to make sure they are safe. Quality control helps find problems early. This keeps straws up to industry standards.

Choose packaging and storage that is good for the planet. This keeps straws fresh. It also helps eco-friendly efforts.

When you make paper straws, you must pick good materials. The paper, glue, and other things you use matter a lot. If you choose safe and strong materials, your straws will last in drinks and keep people healthy.

There are different kinds of paper for making paper straws. Each kind has special features that change how strong, safe, or green the straw is.

Type of Paper | Key Properties |

|---|---|

Food-grade paper | Comes from renewable sources, has a water-resistant coat, breaks down easily. |

Kraft paper | Very strong, made from new wood pulp, processed one time. |

Recycled paper | Softer, made from fibers used many times, not as strong. |

Bamboo paper | Good for the planet, often picked for being eco-friendly. |

Wax paper | Keeps water out but may not break down well. |

Softwood and hardwood pulp | Has long, bendy fibers that make straws tough. |

Tip: Look for certifications like FSC®, BRCGS, ISO 14001:2015, FDA Approval, and EU Food Contact Materials Regulations. These show your paper is safe and good for the planet.

Food-grade paper with a biodegradable coat is best for safe and strong straws. This coat stops straws from getting soggy and helps them break down after use. Picking biodegradable stuff also helps nature.

You need glue to stick the paper layers together. Water-based glue works best for paper straws. This glue is safe for food, strong, and good for the earth. Special water-based glue makes straws stay together in drinks.

Glue must stay strong when wet so straws do not fall apart.

Good glue does not break when wet or hot.

Always use glue that meets food safety and green rules like FDA or EU standards.

Eco-friendly glue is strong, safe, and lasts long.

The right glue helps straws last longer and keeps them safe for people.

You might need extra things to make your straws better. These can make straws stronger or keep water out.

Additional Supplies | Description |

|---|---|

Coatings | Acrylic, wax, or paraffin coats help keep water out. |

Bamboo or Sugarcane Fiber | Mixing with kraft paper makes straws strong and easy to break down. |

Optional Fibers | Used to make straws tougher for thick drinks like smoothies. |

You can add a biodegradable coat to make straws last longer in drinks. This coat also helps straws break down after use. If you want straws for smoothies, you can mix in extra fibers to make them stronger.

Picking the right materials for paper straws helps you make safe, strong, and earth-friendly products.

Getting a paper straw machine ready is very important. You need to think about how much money you will spend. You also need to know what the machine can do. This helps you make good straws. Some companies, like Wenzhou Hongshuo Machinery Co., Ltd. in China, make these machines. They sell many types of machines. Some machines use glue, and some do not. They also make machines for packing boxes, making paper sticks, and cutting shapes. Their machines have important certifications. They sell to Europe, America, and Southeast Asia. They care about making good products and keeping customers happy.

You should plan your money before you buy a customized paper straw machine. The first cost can be $15,000 for a simple machine. It can be over $50,000 for a bigger machine. The price depends on a few things:

What kind of straw machine you pick

How much work the machine does by itself

Extra parts you need to run the machine

When you pick a paper straw machine, look at how fast it works. Also, check what sizes it can make. Here is a table with some common machines:

Model | Outer Diameter Options | Steady Speed (m/min) |

|---|---|---|

VPS-6 | 5mm-12mm | 30-40 |

VPS-10 | 5mm-12mm | 60-80 |

To make straws the right size, you must set up the machine. Most new machines have a touch screen and PLC control. You can change these things:

Inside diameter (4-12mm)

How thick the straw is (0.3-1mm)

How long the straw is (120-1050mm)

How glue is put on (one or two times)

How the machine cuts (many blades with servo control)

You can use speed control to change how fast the motor goes. The encoder helps cut each straw to the right length.

Safety is always important when using a paper straw machine. Always do these things:

Safety Protocols | Description |

|---|---|

Calibrate blade runout | Keep blade runout at or below 0.03 mm to stop rough edges. |

Control glue temperature | Keep glue heat within ±2 °C to stop glue messes. |

Follow HACCP principles | Use safety steps from FDA rules. |

Check all safety parts before you start the machine. This keeps workers safe and makes sure straws are good quality.

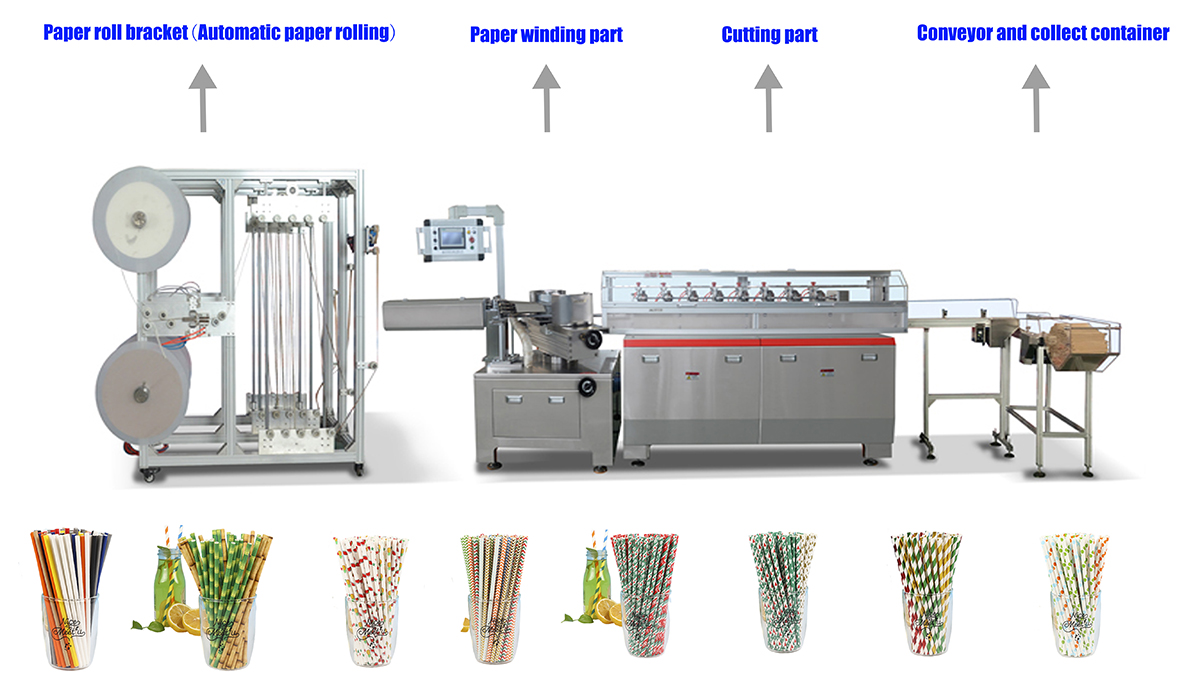

You use a paper straw making machine to change raw materials into paper straws. This process has many steps. Each step helps make straws that are strong, safe, and good for the planet. The straw making machine uses automation to work faster and keep quality high. Modern machines can make thousands of straws every hour.

First, you put rolls of paper on the straw making machine. The paper rack holds these rolls in place. You can add more racks if you need to make more straws. The machine unwinds the paper strips and moves them to the next step. Automation means people do not need to help much. The process stays steady and smooth. You can watch the feeding as it happens. This helps you stop jams and mistakes.

Tip: Pick food-grade paper rolls for better results. This keeps your straws safe and helps the planet.

The straw making machine puts glue on the paper strips. You use glue that is safe for food and breaks down easily. This glue sticks the layers together well. It does not break when wet or hot, so straws stay strong in drinks. The machine spreads glue evenly on each strip. This is important for safety and how well the straws work. You set the glue amount with exact controls. This makes sure every straw is safe to use.

Automation here means you use less glue. You can save up to half the glue compared to old machines. This saves money and helps nature.

After gluing, the machine rolls the paper strips around a steel pipe mold. You can change the mold to make different straw sizes and shapes. Rolling and forming is quick and exact. The machine uses a round knife or saw blade to cut, and a PLC system controls it. This keeps the process steady and stops mistakes.

Component | Description |

|---|---|

Paper rack | Holds many paper rolls, you can adjust for how much you want to make. |

Roll paper part | Uses steel pipe molds to make different straw shapes and sizes. |

Slitting part | Uses round knives or saw blades to cut, controlled by PLC. |

Conveying part | Gives extra space for smooth production. |

Automation in rolling and forming makes sure all straws look the same. You can make more straws quickly with fast machines.

The machine cuts the rolled paper straws to the right length. You use special cutting tools for this step. Making straws the same length is important for quality and happy customers. The machine uses servo motors and encoders to control cutting. This means less waste because each straw is cut just right.

You can pick the length for different straw types, like cocktail or smoothie straws. Automation keeps cutting fast and steady.

You need to dry the straws before you pack them. The machine has a drying part for this job. Drying stops glue problems and keeps straws strong. You control the drying to stop humidity issues. After drying, you check for any wet spots. The machine can also shape the tips and add a final coat.

The process has steps like unwinding, gluing, winding, coating, drying, checking, tip shaping, cutting, and packing.

Drying is very important to stop glue problems and slowdowns.

You check for leftover moisture before packing.

Automation in drying and finishing helps keep quality the same. You can check each straw with vision systems. This lowers mistakes and makes straws safer.

Note: Fast, straight production lines use less glue and energy. You save money and help the planet. New machines make glue-free, PFAS-free, and compostable paper straws. You can make more straws and use less energy.

You finish by packing the paper straws. Automation in every step—from feeding to finishing—helps you make lots of straws with few mistakes. Your production stays fast, and your straws are safe for people to use.

Quality control makes sure paper straws are safe and strong. You need to check each step to stop problems. This helps keep customers happy and safe.

There are different ways to check straws during production. You can look at straws to find cracks or glue marks. Machines with cameras can scan straws for mistakes. Some factories put straws in water to see if they keep their shape. You should also measure the length and width of each straw. This makes sure all straws meet your standards.

Tip: If you check often, you find problems early and waste less.

Some problems happen a lot with paper straws. These issues can make straws unsafe or weak. Here is a table that lists the main problems and how to stop them:

Defect Type | Description | Prevention Method |

|---|---|---|

Disintegration when exposed to liquid | Straws break and lose shape in drinks, which can cause choking. | Use strong, water-resistant materials. |

Low-grade adhesives | Straws get soggy and fall apart because the glue is weak. | Use better glue in the process. |

Single-layer structure | Straws with one layer do not last long. | Make straws with more layers for strength. |

Poor production processes | Bad manufacturing makes straws break down fast. | Use strict quality checks in production. |

You can stop most problems by using good materials and following the rules.

You need to make sure your paper straws follow world safety and quality rules. These rules protect people and help you sell in more places. Here are some important rules and standards:

Standard/Regulation | Description |

|---|---|

FDA Regulations | U.S. food safety rules for things that touch food. |

EU Environmental Guidelines | European Union rules for safety and the environment. |

ISO Certification | International rules for quality management. |

HACCP Certification | Food safety management system. |

Regulation | Description |

|---|---|

Food Contact Materials Regulations 2004 | EU rules for things that touch food. |

Materials and Articles in Contact with Food 2019 | Safety rules for food contact materials. |

Regulation | Description |

|---|---|

BfR XXXVI | German and EU food safety for paper and cardboard. |

FDA 176.170 | U.S. law for paper and board used with food. |

You should follow these rules to keep straws safe and ready to sell. Meeting these standards helps people trust your straws and helps your business grow.

There are many ways to pack paper straws. Good packaging keeps straws safe and helps the planet. Many companies pick green packaging to help nature. Some use big boxes for stores and restaurants. Others sell striped or plain straws in bulk. You can also find small packs with fun designs. Some packs use compostable materials and food-safe ink. This makes them break down and keeps them safe for nature.

Packaging Type | Description |

|---|---|

Bulk Packaging | Good for businesses, comes in many types. |

Striped and Plain | Many choices for big orders. |

Standard Size | Has striped and plain white straws for stores. |

You can buy Green Stripe Compostable Paper Straws made with FSC paper and soy ink. Hongshuo Paper Drinking Straws use PEFC paper and kraft wrapping. Rigid Fiber Paper Straws use wood fibers and skip bad chemicals. These options give you a green way to pack straws.

Storing paper straws the right way keeps them strong. Put straws in a cool, dry spot. Do not let them get wet or sit in the sun. Keep straws in their packs until you need them. Room temperature is best for storage. If you store them well, straws last 12 to 24 months. Look at the dates and use old straws first. Good storage keeps straws nice and helps the earth.

Store in a cool, dry spot.

Keep out of sunlight.

Leave straws in packs until needed.

Use old straws before new ones.

Choosing green habits helps the earth. Paper straws break down in one or two months. Plastic straws take hundreds of years to go away. Paper straws break down fast and make less trash. Making paper straws uses less plastic and lowers carbon footprints. You can pick packs made from safe paper and materials that break down. These choices help the planet and support green living.

Tip: Using green packs and storing straws right helps the earth and your business.

Using paper straws and green packs shows you care about nature. These steps help the planet and make the future better.

You can make more paper straws by using smart ideas. Automation lets machines work faster and with fewer errors. Manufacturing execution systems, or MES, help control the whole process. They keep everything running smoothly. Real-time monitoring lets you watch things like paper tension and sealing heat while the machine works. Predictive analytics use AI to warn you when parts need fixing. This stops long delays and keeps your line moving.

Strategy | Description |

|---|---|

Automation | MES controls speed and cuts down on waste. |

Real-time Monitoring | Checks paper tension and cutting as you go. |

Predictive Analytics | AI tells you when to fix things to avoid stops. |

Clean glue nozzles often so they do not get clogged. Calibrate paper tension so the paper does not rip. Use good materials to stop jams in the machine. Test your straws often to make sure they are safe and strong.

You can make less waste by picking green materials and cutting smart. Good cutting makes sure each straw is the right size. This way, you do not throw away extra pieces. Recycle scraps from the process to use all your material. These steps save money and help the earth.

Pick green materials for your straws.

Use cutting machines that make less waste.

Gather and recycle leftover paper.

Taking care of your machines helps you make more straws. Calibrate sensors and adjust feed systems for your materials. Set straw length, thickness, and speed on the digital screen. Cameras and sensors check for problems with straw shape and size. AI tells you when to fix parts before they break. Teach your team to read data and act fast when there are alerts.

Maintenance Practice | Description |

|---|---|

Initial Setup and Calibration | Adjust sensors for your straw materials. |

Programming Production Parameters | Set straw size and speed on the machine. |

Quality Monitoring | Use cameras to check straw shape as you work. |

Regular Maintenance Alerts | AI tells you when to fix parts. |

Operator Training | Teach your team to use data screens. |

Tip: Doing regular checks and using smart tools helps you make more straws with fewer problems.

You can make paper straws well if you follow each step. Pick fast machines and use automation to make more straws. This also helps keep the straws good quality. Use biodegradable coatings and natural adhesives for strong, safe straws. These are better for the earth. Choose recycled paper and plant-based inks to help the planet. This lowers your carbon footprint. Good quality control systems help you meet tough rules. The table below lists main techniques and what they do:

Technique | Benefit |

|---|---|

Biodegradable coatings | Make straws last longer and keep out water |

Natural adhesives | Safe for compost and people |

Recycled paper sources | Help lower harm to the planet |

If you use these ways, you help nature and support green living.

You should use food-grade paper with a biodegradable coating. This paper keeps straws strong in drinks and breaks down quickly after use. Look for certifications like FSC® or FDA approval.

You can add a water-resistant coating to the paper. Use strong, food-safe glue. Store straws in a cool, dry place. These steps help straws last longer in drinks.

Some machines let you make glue-free paper straws. You use special technology to bond the paper layers. Wenzhou Hongshuo Machinery Co., Ltd. offers high-speed machines for both glue and glue-free production.

A modern paper straw machine can make thousands of straws every hour. Production speed depends on the machine model and settings. Some machines reach up to 80 meters per minute.

You should check for CE, FDA, ISO, and FSC® certifications. These show the products meet safety and environmental standards. Certified machines and straws help you sell in more countries.