T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2026-02-13 Origin: Site

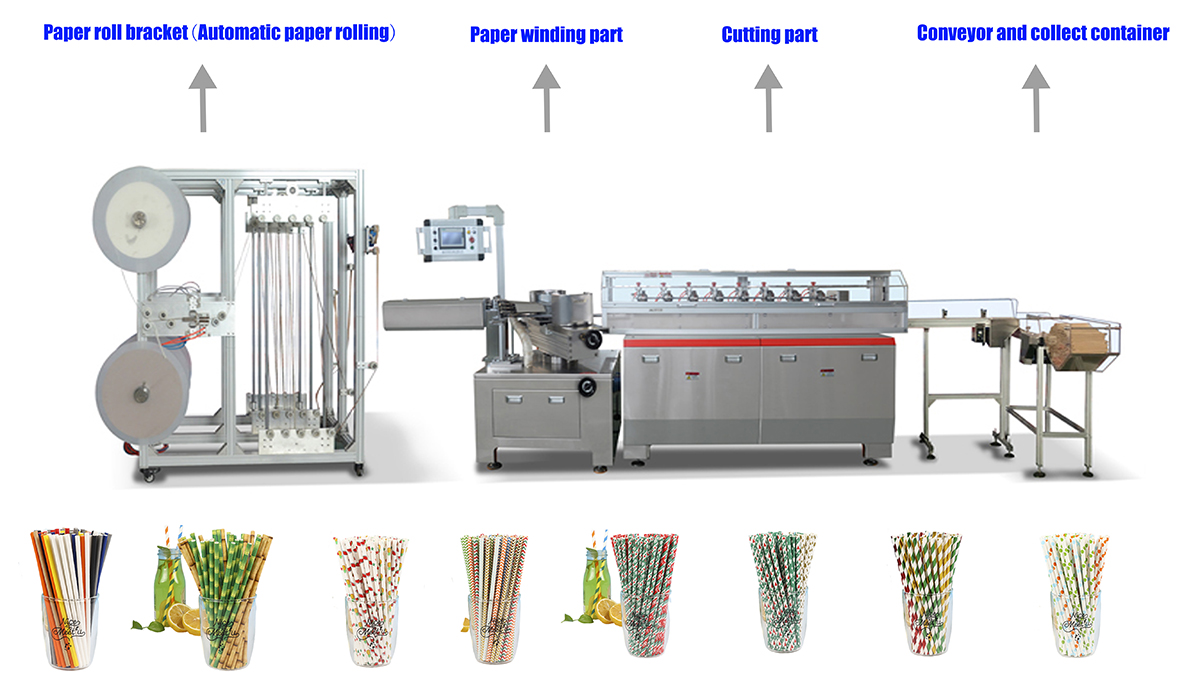

A paper straw looks easy to make. Yet one small drift can raise scrap fast. A paper straw machine needs tight control every step.

In this article, we explain how paper straws are made in real factories. You will learn the key steps from rolls to packing. You will also see what a paper straw machine must control for stable quality.

Most production starts at the paper roll. Buyers usually pick food-grade paper from approved mills. The roll then gets slit into narrow strips for each layer. Strip width must match the straw diameter and ply design. If width shifts, the seam position shifts too.

Roll handling matters more than many teams expect. You want clean edges and stable winding hardness. You also want predictable moisture content inside the roll. If rolls sit in damp storage, paper softens and dust rises. Feeding becomes unstable and jams become more frequent. A good prep routine keeps the paper straw machine calm and repeatable.

The machine forms a tube around a mandrel. Many lines use spiral winding for flexible sizes. The strip wraps in layers, then bonding holds the seam. Bonding can use water-based adhesive or other bonding approaches. The best choice depends on your market and claims.

Forming is a balance between speed and control. Tension keeps layers tight and aligned. Alignment keeps the seam centered and consistent. If tension drifts, you may see oval straws or weak seams. If alignment drifts, you may see uneven wall thickness. Operators should watch the seam line and tube roundness constantly. Those are early signals before a defect wave starts.

Tip:Ask operators to check seam position every 30 minutes during long runs.

After forming, the tube needs drying or curing. This step stabilizes shape and stiffness. It also reduces moisture that can cause later deformation. Drying uses heat and airflow in many line designs. The goal is steady output, not maximum heat.

Too little drying leaves straws soft and easy to deform. Too much heat can darken paper and add odor risk. It can also increase brittleness at the cut edge. Line speed, airflow, and temperature must match your paper grade. If you change paper suppliers, you should retune drying quickly. A controlled drying step protects quality during storage and shipping.

The long tube becomes sellable pieces at the cutter. The cutter uses timing signals to hit target length. Blade sharpness decides edge quality and burr level. Sensor cleanliness decides length consistency and stable timing. Collection systems then stack or convey straws for packing.

Cut quality is more than appearance. Burrs can feel rough and shed dust into packs. Uneven length can break automated wrapping and counting. A stable paper straw machine keeps cutting smooth at production speed. You should plan blade inspection as a daily habit. You should also keep the cut zone clean during the shift. Dust buildup is a common root cause behind length drift and jams.

Process steps and the control points buyers should care about

Process step | Key control points | Common issues if control drifts |

Slitting and prep | Strip width, edge quality, roll storage | Jams, seam shift, excess dust |

Forming and bonding | Tension, alignment, bonding stability | Ovality, seam lift, weak strength |

Drying and curing | Temperature, airflow, line speed | Soft straws, odor, discoloration |

Cutting and collecting | Blade condition, sensor timing, cleanliness | Burrs, length drift, packing stops |

Many paper straws use a multi-ply build. A common design uses three plies, yet designs vary by market. Inner layers can focus on stiffness and wet strength. Outer layers can focus on print quality and smooth feel. Ply direction also matters, since fiber direction changes bending behavior.

Paper choice affects almost every downstream setting. Heavier paper can improve stiffness, yet it may reduce stable speed. Lighter paper can run fast, yet it may soften sooner in drinks. You should choose paper based on drink type and customer expectations. You should also consider storage and shipping climate. A paper straw machine can only do so much if paper is unstable.

Bonding keeps the seam closed during real use. Many factories use water-based adhesives designed for food packaging. The adhesive must bond fast at production speed. It also must stay stable during shipping and storage. If bonding is inconsistent, seam lift becomes a repeat complaint.

Buyers often ask “food-safe” as a broad term. In practice, they want documents and traceability. They also want stable results across batches. Your team should request the same documentation set for every adhesive lot. You should also run a simple seam check during each batch. It helps you catch drift before packing starts.

Coatings aim to extend drink time and reduce sogginess. They can also improve mouthfeel and reduce fuzz. Some coatings support certain recycling or repulpability goals in specific markets. Claims should match local disposal reality and buyer requirements.

Coatings also change production behavior. They can change friction during feeding and forming. They can change how the cut edge behaves at the blade. They can also change odor risk if curing is not stable. If you use coated paper, tune your process around it. Test coated paper in your actual drink menu before full scale.

Note:Material changes require process changes, even if the machine stays the same.

End users do not read specs at the café. They judge the straw in seconds. A good straw stays firm long enough to finish the drink. It also keeps a paper-like feel on the lips. Coatings can help reduce water uptake and swelling. Adhesives can help keep the seam sealed during sipping.

Trade-offs are real in this space. A stronger barrier can reduce sogginess, yet it may change recycling perception. A strong seam can raise durability, yet it can add odor risk if chemistry is off. Buyers should define the most important outcome first. Then they can choose the right material and process path. That approach prevents endless trial cycles.

Taste complaints can destroy repeat orders quickly. Odor often comes from storage, curing, or contamination. Paper can absorb surrounding smells during storage. Adhesives and coatings can also add odor if curing is incomplete. Clean production and clean storage reduce these risks.

You can run a simple sensory check during sampling. Use plain water, then test a target drink next. Use a small panel inside your team for consistency. Store samples for a short time and retest later. If odor grows after storage, you may have curing or storage issues. Fix those issues before you scale the line. It saves you from large returns later.

Different drinks stress different weaknesses. Cold drinks stress long soaking and slow swelling. Hot drinks stress heat softening and seam stability. High-sugar drinks can increase stickiness and surface residue. Bubble tea adds a wider diameter and more bending stress.

A paper straw machine must match your target drink set. If you sell to cafés, test coffee, tea, and iced drinks. If you sell to bubble tea chains, test thick sizes in long soak sessions. If you sell to hotels, test storage and humidity stability. Matching materials to real drinks protects your brand and reduces replacement costs.

Tip:Always test your top three drinks before you approve a new material lot.

Quality control works best when it follows the process flow. We start at incoming paper and bonding materials. We check roll edges, winding hardness, and basic moisture stability. During runs, we watch seam look, tube roundness, and cut edges. After cutting, we confirm length consistency and dust level. Then we pack only when results stay stable. A paper straw machine rewards disciplined checks because it reduces scrap waves.

Checkpoint stage | What to check | Why it matters | What to record |

Incoming paper | Edge quality, curl, odor, roll hardness | Prevents jams and seam drift | Roll ID, storage date |

Forming and bonding | Seam line, roundness, tube stiffness | Protects durability in drinks | Settings, defect photos |

Drying and curing | Temperature stability, airflow, color change | Prevents soft straws and odor | Zone readings, time |

Cutting and collecting | Blade sharpness, length drift, burrs | Protects packing speed and feel | Length samples, blade hours |

Packing release | Dust, odor, batch code, carton integrity | Protects buyer trust | QC pass sheet |

Factories should keep one “golden sample” per SKU. It shows the target seam and cut edge. Operators compare current output to it during shifts. It reduces debates and speeds training for new staff. A stable routine protects yield and repeat orders.

Many procurement teams start with simple tests during sourcing. They often run a soak test in water or a target drink. They then check seam integrity after soaking and light stirring. Next, they inspect cut quality and dust in the pack. Some teams also run a quick sip test for odor and taste. These tests are fast, cheap, and repeatable.

We should keep one standard test sheet for every sample batch. Use the same cup size, drink temperature, and time points each time. Use the same scoring language for every supplier. This makes comparisons fair and easy to defend internally. If you later add lab tests, you still keep this screening step.

Hygiene expectations keep rising in many markets. Buyers want clean handling and clean packing zones. They also want traceability for paper rolls and batches. Batch codes help them manage complaints and returns. They also help you isolate issues without broad recalls. A paper straw machine line needs clear records to stay audit-ready.

A practical plan uses three habits. First, keep dust control near cutting and packing zones. Second, reduce manual touches where you can. Third, keep cleaning logs and training records for every shift. Traceability needs clear run records and versioned materials files. These records support audits and renewals for large buyers.

Tip:Keep a one-page QC sheet for each batch, then store it digitally.

Packaging should be planned like a production step. If we treat it as “after work,” problems show up fast. A paper straw machine can cut clean and steady. Yet packaging still fails if length drifts or dust rises.

● Bulk pack suits high-volume buyers and fast picking.

● It needs accurate counting and clean bins.

● Individual wrap suits hygiene-driven channels.

● It needs stable length and low dust output.

● Retail boxes need strong visual control and low defects.

● They also need stable print and clear batch coding.Choose packaging based on buyer needs and total cost. Bulk packing needs space for counting and carton staging. Wrapping needs space for film rolls and sealing checks. If packaging stops often, real capacity drops fast. Stable cutting and daily cleaning make packing smoother and cheaper.

Distribution can damage straws even if production is perfect. Moisture is the first enemy during shipping. Compression is the second enemy on pallets. Heat can also shift stiffness during long routes.

● Use humidity-resistant cartons for wet routes.

● Add inner liners for long storage or sea freight.

● Pack tight enough to stop movement and bending.

● Avoid over-tight packs that crush edges and tubes.

● Store finished goods away from chemicals and strong odors.

● Keep warehouse humidity steady to reduce softening.A stable warehouse plan protects taste and shape. It also reduces claims from crushed cartons and deformed straws.

Many buyers choose paper straws for environmental reasons. Still, we should avoid broad claims. Disposal rules vary by city and recycler. Some buyers care about paper stream fit. Others care about compost programs or waste reduction.

● Describe what the straw is designed to do.

● Avoid “recyclable everywhere” language in labels.

● Avoid “always compostable” language in bids.

● Match claims to the buyer’s region and channel.

● Offer documents and test summaries when asked.

● Keep wording consistent across packaging and sales files.Note:Align environmental claims to local disposal rules and buyer guidance.

Paper straws are made through a controlled factory flow. Paper gets prepared, formed, dried, cut, checked, and packed. Each step protects strength, taste, and stable length. A good paper straw machine keeps tension and cutting consistent.

Wenzhou Hongshuo Machinery Co., Ltd. supports buyers who want reliable paper straw machine production. Their equipment and OEM support help teams scale output and reduce scrap. Their service guidance helps you set specs, run trials, and keep quality steady.

A: Rolls are slit, formed into tubes, bonded, dried, cut, checked, and packed. A paper straw machine runs these steps in a controlled flow.

A: It feeds slit paper strips and forms them around a mandrel. Stable tension and alignment keep the seam consistent.

A: Paper grade, bonding quality, and drying control all matter. A paper straw machine can also create defects if tension or curing drifts.

A: They use soak tests, seam checks, and cut-edge inspections. They also check odor and dust in the pack.

A: It depends on the channel. Bulk packs need clean counting, while wraps need stable length and low dust from the paper straw machine.