T: +86-18066442232

E: sylvia@wzhongshuojixie.com

E: sylvia@wzhongshuojixie.com

Wanquan Industrial Zone, west of National Road 104, Sunlou Village, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province

Views: 0 Author: Site Editor Publish Time: 2025-09-24 Origin: Site

Have you ever wondered how the boxes that hold your favorite products are made? Box making machines play a crucial role in various industries, ensuring efficiency and quality.

In this article, we’ll explore what these machines are called and delve into the world of paper box machinery. You’ll learn about their types, features, and applications.

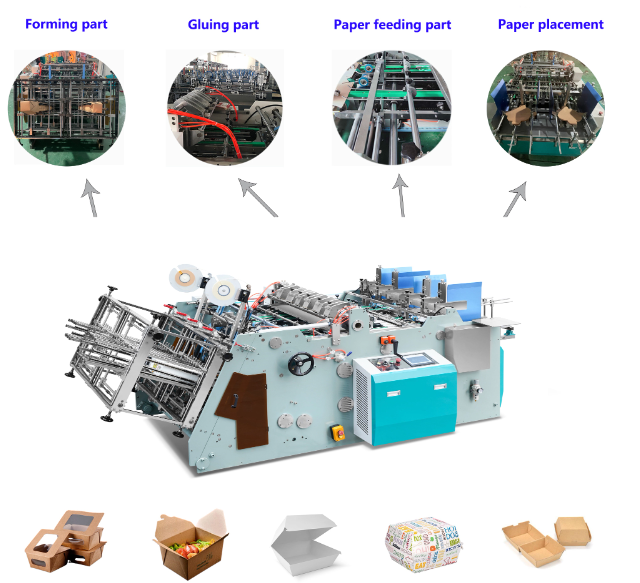

A box making machine is a specialized device designed to create boxes from various types of paper or cardboard. These machines automate the process, making it faster and more efficient than manual methods.

Typically, they perform several functions, including:

● Feeding: Automatically feeding sheets of material into the machine.

● Slotting: Cutting slots for folding.

● Scoring: Creating fold lines for easy assembly.

● Gluing: Applying adhesive to secure the box structure.

● Forming: Shaping the box into its final form.

This automation significantly reduces labor costs and production time.

Paper box machinery is essential in today’s manufacturing landscape. Here are a few reasons why:

1. Efficiency: These machines can produce large quantities of boxes in a short time. For example, some models can create hundreds of boxes per hour.

2. Consistency: Automated processes ensure that each box is made to the same specifications, minimizing errors.

3. Versatility: They can handle various materials, including corrugated cardboard and specialty papers. This versatility allows manufacturers to meet diverse packaging needs.

4. Sustainability: Many modern machines are designed with eco-friendly practices in mind. They reduce waste and energy consumption during production.

5. Customization: Advanced box making machines allow for custom designs, catering to specific customer requirements.

This flowchart highlights how each step contributes to the final product, showcasing the machine's efficiency.

In summary, box making machines are crucial for producing high-quality packaging solutions. Their role in modern manufacturing cannot be overstated, as they enhance productivity while meeting the growing demands of various industries.

When it comes to box making machines, there are two main types: automatic and manual. Each has its unique features and benefits.

Automatic Machines

● Efficiency: These machines can produce a large number of boxes quickly. Some can make hundreds per hour.

● Consistency: They ensure uniformity in box production, minimizing human error.

● Labor Savings: Fewer workers are needed, reducing overall labor costs.

Disadvantages:

● Higher Initial Cost: The upfront investment is significant.

● Maintenance: They require regular maintenance and skilled operators.

Manual Machines

● Cost-Effective: Lower initial purchase price makes them accessible for small businesses.

● Flexibility: Easier to switch between different box designs or sizes.

Disadvantages:

● Time-Consuming: Slower production rates compared to automatic machines.

● Inconsistent Quality: More prone to human error, leading to variations in output.

Feature | Automatic Machines | Manual Machines |

Production Speed | High | Low |

Initial Cost | High | Low |

Labor Requirement | Low | High |

Quality Consistency | High | Variable |

Specialized box making machines are designed for specific applications. They cater to unique packaging needs, enhancing efficiency in those areas.

Examples of Specialized Machines:

1. Food Container Machines:

These machines create boxes specifically for food items, ensuring hygiene and safety. They often include features for sealing and insulation.

2. Retail Packaging Machines:

Designed for products sold in stores, these machines produce eye-catching boxes that enhance branding. They can handle complex designs and custom prints.

3. Corrugated Box Machines:

Ideal for shipping and storage, these machines create sturdy boxes. They often include slotting and scoring features to ensure strength and durability.

Key Benefits of Specialized Machines:

● Tailored Solutions: They meet specific industry standards and requirements.

● Enhanced Production: Specialized features streamline the production process for particular box types.

This highlights how different machines serve various needs in the packaging industry. Each type plays a vital role in ensuring that businesses can meet their packaging demands effectively.

Modern paper box machinery often features all-in-one systems, combining multiple functions into a single unit. This integration simplifies the box-making process and enhances productivity.

● Capabilities: These machines can handle various tasks, including:

○ Feeding: They can load 20–50 sheets at a time, streamlining the initial stage.

○ Slotting: Cuts precise slots for easy folding.

○ Scoring: Creates fold lines to ensure clean edges.

○ Die-Cutting: Shapes boxes according to specific designs.

○ Gluing: Applies adhesive to secure the box structure.

○ Forming: Shapes the flat material into a finished box.

This multi-functionality reduces the need for multiple machines, saving space and costs.

The types of materials used in box making are crucial for quality and performance. Here are some common materials:

● PE-Coated Paper: Ideal for food packaging due to its moisture resistance.

● Corrugated Board: Provides strength and durability for shipping boxes.

● Fanfold Cardboard: Supports widths up to 2.8m, perfect for larger boxes.

Importance of Material Selection: Choosing the right material affects not only the box's strength but also its appearance and functionality. It ensures that the final product meets specific industry standards.

Customization plays a significant role in the versatility of paper box machinery. Here’s how:

● Rapid Mold/Die Changes: Machines can switch molds in 60 seconds or less. This speed is crucial for production efficiency, allowing quick adjustments for different designs.

● Double-Station Models: These machines can boost output by up to 50%. For instance, dual lanes can produce burger boxes simultaneously, increasing productivity.

● Single-Station Machines: Perfect for niche designs like cake boxes. They focus on quality and precision for specialized products.

Feature | Double-Station Models | Single-Station Models |

Production Speed | High | Moderate |

Design Versatility | Limited | High |

Ideal Use | Bulk Production | Custom Designs |

Sustainability is becoming increasingly important in the packaging industry. Modern paper box machinery incorporates eco-friendly features:

● Precision Cutting: Reduces waste by ensuring clean cuts, eliminating burrs that can lead to material loss.

● Energy-Efficient Servo Motors: These motors consume less power, contributing to lower operational costs and a smaller carbon footprint.

Importance of Sustainability: As consumers become more environmentally conscious, businesses are focusing on sustainable practices. Eco-friendly machinery supports this shift, making it essential for modern manufacturers.

This chart emphasizes how various features work together, enhancing the overall efficiency and effectiveness of paper box machinery.

The box making machine industry is constantly evolving. Innovations are reshaping how manufacturers produce boxes, making processes more efficient and adaptable. Here are some key advancements in paper box machinery.

Modern machines are designed to cater to small orders, offering what is often referred to as "instant box freedom." This flexibility allows businesses to produce anywhere from 10 to 500 units without long setup times.

● Benefits:

○ Reduced Waste: Smaller runs mean less excess inventory.

○ Quick Turnaround: Businesses can respond faster to market demands.

○ Customization: More options for tailored designs without significant cost increases.

This capability is particularly valuable for companies that need to test new products or respond to niche markets.

Some of the latest machines are built to handle thick corrugated materials, accommodating up to 2mm in thickness. This is crucial for industrial packaging needs.

● Advantages:

○ Durability: These machines create boxes that can withstand heavy loads.

○ Versatility: Suitable for various applications, from shipping to storage.

○ Cost-Effective: Reduces the need for additional protective packaging.

Material Type | Thickness (mm) | Ideal Use |

Standard Corrugated | Up to 1.5 | General packaging |

Heavy-Duty Corrugated | Up to 2.0 | Industrial applications |

Advanced systems are now incorporating 3D forming technology, which utilizes vacuum suction and multi-step folding. This innovation allows for the creation of complex shapes, such as:

● Gable-Top Boxes: Ideal for beverages and food products.

● Pizza Trays: Designed for easy stacking and transport.

Key Features:

● Precision: Ensures accurate shapes and sizes.

● Efficiency: Reduces manual labor and speeds up production.

This technology not only enhances the aesthetic appeal of packaging but also improves functionality.

Modular designs are gaining traction in the industry. These systems allow for easy upgrades and customization, enabling manufacturers to adapt to changing needs.

● Potential Add-Ons:

○ Printing Modules: For on-demand branding and labeling.

○ Die-Cutting Stations: To enhance design capabilities without purchasing new machines.

Benefits of Modular Designs:

● Scalability: Companies can expand their capabilities as needed.

● Cost Savings: Avoids the expense of entirely new machines.

● Flexibility: Easily switch between different production requirements.

These innovations reflect how the industry is adapting to meet modern demands, enhancing efficiency and product quality in the process.

Paper box machinery plays a crucial role across various industries. From food packaging to retail, these machines help create efficient and attractive packaging solutions. Let’s explore some of the key sectors benefiting from this technology.

The food and beverage sector relies heavily on paper box machinery for packaging solutions that are both functional and appealing. Here are some common applications:

● Lunch Boxes: Ideal for takeout and meal prep services, these boxes keep food fresh and secure.

● Burger Cartons: Designed for easy stacking and transport, they maintain the burger's shape and integrity.

● Sushi Trays: Specially designed to showcase sushi, often with compartments for sauces and wasabi.

Product Type | Key Features |

Lunch Boxes | Insulated, easy to carry |

Burger Cartons | Sturdy, grease-resistant |

Sushi Trays | Compartmentalized, appealing |

These packaging solutions not only enhance presentation but also ensure food safety.

In the retail sector, box making machines are essential for creating attractive packaging that draws customers in. Here’s how they are used:

● Gift Boxes: Customized designs for special occasions, often featuring vibrant colors and prints.

● Cosmetics Cartons: Sleek and stylish packaging that protects products while promoting brand identity.

● E-commerce Mailers: Durable boxes designed for shipping products safely, often with branding options.

Key Benefits:

● Brand Visibility: Eye-catching designs enhance marketing efforts.

● Protection: Keeps products safe during storage and transport.

● Sustainability: Many retailers are moving towards eco-friendly materials.

Box making machinery is also vital in industrial applications. It produces robust packaging solutions that meet the demands of heavy-duty use.

● Corrugated Shipping Boxes: Designed to withstand rough handling during transportation, ensuring products arrive safely.

● Heavy-Duty Storage Containers: Ideal for storing large items, these boxes provide maximum strength and durability.

Application Type | Features |

Corrugated Shipping Boxes | Lightweight, strong, customizable |

Heavy-Duty Storage Containers | Thick materials, stackable |

Industry Importance:

● Efficiency: Streamlines the packaging process, saving time and resources.

● Cost-Effectiveness: Reduces packaging costs with bulk production.

These sectors demonstrate the versatility and significance of paper box machinery in today’s market, catering to diverse packaging needs.

A: Box making machines enhance efficiency, reduce labor costs, and allow for customization. They produce high-quality boxes quickly, minimizing waste and ensuring consistent packaging standards.

A: A box making machine operates by feeding paper or cardboard into the system, where it is cut, folded, and glued into the desired box shape, often utilizing automated processes for speed and precision.

A: Paper box machinery can create various boxes, including corrugated shipping boxes, gift boxes, food containers, and custom designs for retail and industrial use.

A: The cost of a box making machine varies widely, typically ranging from a few thousand to several hundred thousand dollars, depending on the machine's capabilities and features.

A: Consider factors such as production volume, box types, automation level, available space, and budget. It's also essential to evaluate the machine's durability and service support.

Box making machines are vital in various industries. They enhance efficiency and reduce costs in packaging.

As technology advances, paper box machinery will continue to evolve. This evolution will lead to more innovative and sustainable packaging solutions.

The future looks promising, with increased customization and automation shaping the industry landscape.